Reduce Stress and the Risk of Employee Injury

Any time your employees have to maneuver bulk loads of a material, there accompanies a risk of stress, strain and possible injury for them. As a concerned employer, you certainly want to minimize those risks in order to keep your valued employees safe and productive.

Try Out These 4 Simple Tips to Ease the Strain of Your Bulk Handling Needs

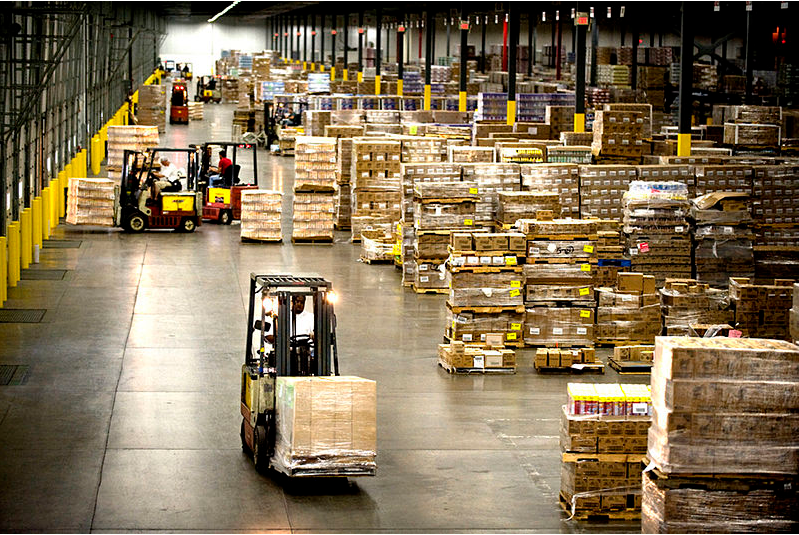

There are many ways to relieve the burden on your hardworking employees in the warehouse to ensure good health and happiness. With this approach, you can more easily reduce employee turnover and lack of productivity. Explore the following 4 simple tips to see if they might help tighten up your bulk material handling practices.

1. Plan Ahead for Large Projects

By looking at large upcoming shipments and planning your employee schedule ahead, you can avoid placing excess pressure on too few employees to handle the load. You might consider enlisting the help of a temporary staffing agency to bring in a few additional employees for the project then going back to normal staffing upon completion.

2. Make the Most Out of Your Power Conveyor Chain System

A power conveyor provide solutions in situations where you have a bulk load of items to move, but you have limited overhead space in which to do so. A power conveyor features a side-by-side track mechanism to streamline product transportation and storage and is capable of handling up to 1,000 pounds of product. This piece of equipment can greatly increase throughput, minimize space requirements and reduce issues for employees. Warehouse owners and managers will find two major types of these conveyor systems, which are a heavy duty over and under conveyor and an inverted floor mounted conveyor.

3. Place Shipments Strategically

Sometimes easing the process is simply a matter of location. If you advise your team about the best location to place the shipment, as well as completely clearing the space in advance, you can avoid the need for excessive transfers of location later.

4. Hold Regular Material Handling Workshops

Provide your team with a series of best practices material handling workshops with tips on how to properly lift, carry and set down heavy loads. Employees might take a training session on handling assistive equipment like power conveyors and transport vehicles to move loads.

Keep Searching for New Ways to Keep Employees Safe

There are many other ways out there to keep your valued employees safe on your warehouse floor. Hopefully these give you a good start before expanding your search.