Did you know that the Co2 laser is one of the earliest gas lasers that was ever created? It might be one of the earlier lasers ever developed, but it’s by far one of the most useful. This laser offers incredible performance and excellent levels of control, which makes it ideal for various applications where precise control and a level of customization are necessary. Not only that, but this laser is one of the most popular for businesses that need mass production of laser engraved goods. It also allows for a wide variety of materials to be used, making it perfect for crafters of all kinds, whether they’re just weekend hobbyists or need them for industrial applications.

How Does a Co2 Laser Work, Exactly?

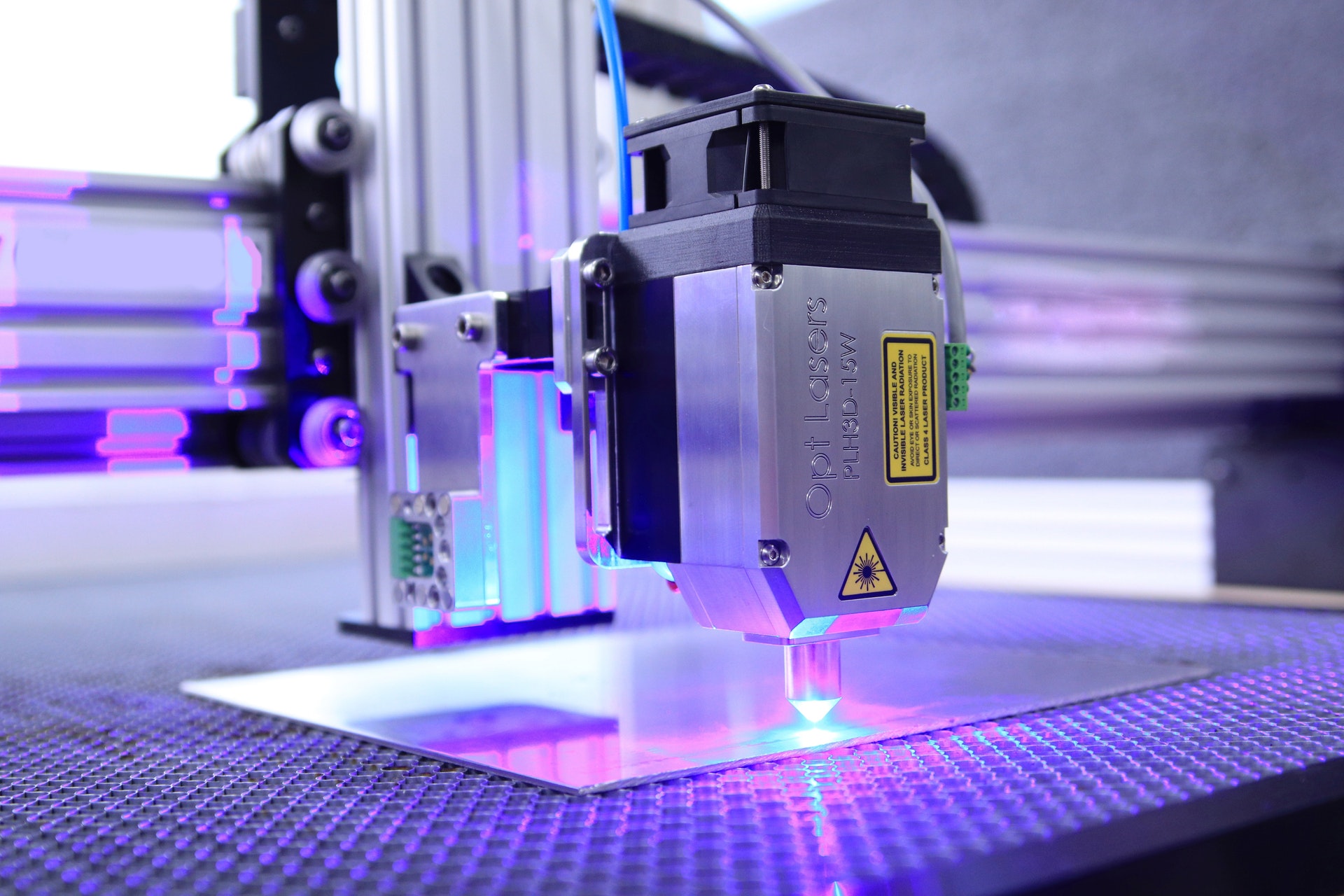

One of the best Co2 lasers to get is from Boss Laser. The LS1416 model they offer is perfect for beginner engravers because it’s easy to use yet still provides extraordinary performance. It also has a wider standard engraving area, making it ideal for larger applications too. Co2 laser engravers work by running electricity through a tube with mirrors on both ends. The tube is filled with Co2, nitrogen, hydrogen, and helium gas. However, only one of the mirrors is fully reflective. The opposite mirror allows for some light to peek through. These mirrors are significant because they guide the laser beam on the material’s surface to allow for accurate and precise designs.

The Co2 laser’s light is infrared, so it’s invisible to the eye. It’s perfect for cutting a wide array of materials, including:

- Paper

- Glass

- Cloth

- Wood

- Metal

- Leather

They also allow for excellent control when engraving materials. The speed and power can be adjusted to any customization to allow for a comfortable rate during regular operation.

Benefits of Co2 Lasers

A Co2 laser is very beneficial. It offers some truly great benefits to the user, including:

- It’s a much safer technique

A C02 laser is much safer than cutting with a blade. Since it doesn’t have a sharp edge, it allows for much higher safety when using the machine. In fact, the laser beam is fully contained in a tight box to allow for complete safety and security.

- Allows for greater accuracy and precision

One of the best advantages of a laser is that it allows for an exceedingly high level of accuracy and precision. Not only that, but the marks a Co2 laser makes are both very clean and exceptionally smooth, which is why they look so neat and precise when it’s finished.

- No-contact technique

The laser beam doesn’t actually touch the surface of the material being cut. Instead, it uses very high heat to melt or vaporize the material instead. It allows for both the machine and the material to sustain minimal damage.

- Uses less energy

The Co2 laser uses a minimum of energy during regular operation. They also require virtually no upkeep, and the only parts that need replacing are inexpensive.

Try a Co2 Laser Engraving Machine

A Co2 laser engraving machine is one of the most helpful machines developed in 1964 by Kumar Patel. Not only are they exact and accurate, but they also don’t use much energy, implement a no-contact engraving process, and allow for a much safer technique overall. However, you have to try it for yourself. Whether you’re a weekend crafting warrior or interested in opening your own business, a Co2 laser engraver is the perfect machine to start learning on.