Quite a common form of well logging, the innovation of electrical well logging is a fundamental means of determining two of the most important aspects of logging – and electric logging probe in particular is one of the most important sources of data which are available to petroleum geologists in particular.

Electrical well logging operates on a very simple principle that gets more complex the further you look into it.

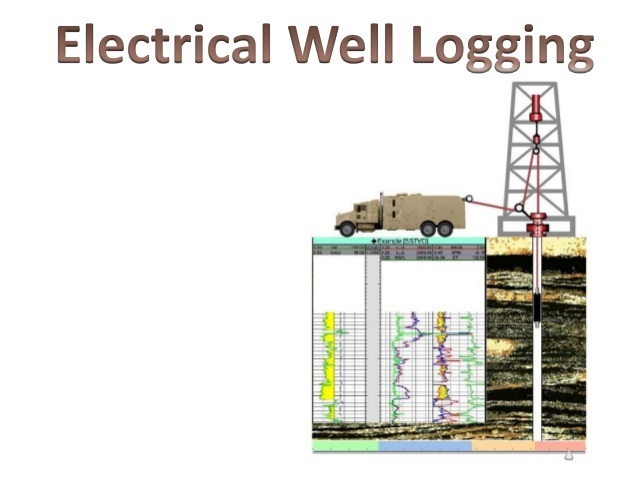

In a nutshell though, an electric-logging truck (though to be honest, any electrical truck is a scientific laboratory on wheels) is employed. The logging company will lower well logging tools in typical fashion into the hole on a wireline from this truck.

Electronic charges are then brought, from the truck, through the wires and administered to the borehole in question in order to create electromagnetic reactions. These reactions cause further reactions with the earth, and the truck is then used to monitor the data which is sent back. This is what is meant by electric logs being generated.

Where it gets a little more complex is that there are hundreds, if not thousands, of different kinds of electric logs, and the geologist has to analyse the area beforehand in order to ascertain which method to use. Typically, offshore and onshore boring efforts are a different kettle of fish entirely, with gamma-ray, calliper, resistivity, density porosity, and neutron porosity all employed in order to learn more about the ground underneath our feet.

There’s no denying it – every single analysis exercise is different, but there are certain things which do stand as principles of the act of geologging – standard throughout most geologging exercises.

Some universal principles of geologging and wireline logging are as follows:

- To obtain a clear reading of a bed, you need to first understand the contributing factors to any test. For instance, the amount of water directly affects the conductivity of any electric well-logging which has a large bearing of the electrodes as they are applied to the test area.

- For the actual logging, an electrode on the surface and an electrode in the well are paired and also polarised. This helps to decipher the readiness of the contents of the well for logging by contrasting the two figures. Depending on the depth that is being traversed, varying frequencies are applied.

- For the electrodes themselves, you can either opt for them in a single or multi form that differs in values for either. If you choose singular then you will find it is cheaper but not nearly as proficient for large-scale operations as they do not have nearly as much lateral penetration.

Despite this, the single-electrode technique still offers as reputably accurate readings as the multi-mode with some speculating that it may even be more advanced. This is down to its exceptional ability to figure out the correlation between wells.

There are one or two drawbacks to this method however as with no water base, a test becomes redundant because no readings will be correct. Therefore, the area usually has to be filled with water or converted to mud.

An unavoidable aspect of any logging is the interference of nature. The curve or gradient at which it’s being logged can invariably drift off to the left in the hole and cause unsuitable conditions.