Machine vision or automated optical inspection (AOI) is referred to as a substitution of the human senses and decision-making ability with image acquisition as well as computer analysis to perform the inspection of a specific item. This process utilizes active imaging technology to automate the inspection and analysis of products in industrial applications. The automation system has become increasingly prevalent in manufacturing sectors. At the moment, machine vision technology has become one of the largest markets for laser diodes all over the world.

If you are considering getting AOI to check your products, check out automated optical inspection system Malaysia. This company has dedicated itself to offering excellent manufacturing test solutions as well as helping the clients liquidate their unused excess. They have a worldwide supply chain as well as excellent customer services.

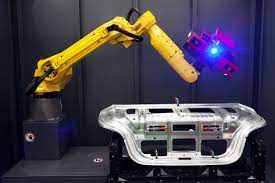

Automated optical inspection with laser sources

Compared to the traditional lights, the laser provides a higher level of contrast with the background image. This allows the computer algorithm to make the calculations with a more precise reference source. Due to this, lasers have been widely used as structural lighting in many image processing options. The machine vision lasers are typically beam-shaped. The shapes can be lines, dots, or other geometric patterns. They are also available in a variety of power and wavelength depending on the requirement of your system.

Automated optical inspection is mainly used to inspect printed circuit boards (PCBs). A camera scans the device via the use of lasers to check for two conditions. One is a quality defect where they check the size and shapes of the components. The other is a catastrophic failure where they look for missing components. AOI is implemented at many stages throughout the manufacturing process like

- Bare board inspection

- Post-flow

- Pre-flow

- Solder paste inspection

- Any other stages where it may be required.

AOI for PCB boards mainly inspect for the following features

- Billboarding

- Component offset

- Component presence or absence

- Excessive solder joints

- Area defects etc.

Another way to check PCB boards

Using an AI is not the only way to check PCB boards. There is another way to check PCB boards as well. You can use LCR meters for this purpose. LCR meters are responsible for measuring the inductance, capacitance, and resistance of electrical equipment.

If you are planning to buy an LCR meter, check out LCR meters Malaysia. The Company MTSE solution is focused on providing test solutions. The LCR meters of this company are very high functioning and last for a very long time.

How do LCR meters work?

The device that is under test is subjected to AC voltage. The LCR meter measures the movement of voltage across and current through the device. The ratio is used to determine the impedance magnitude. The LCR meters also measure the phase angle between the current and voltage in the case of more advanced instruments. Nowadays, with the advent of handheld LCR meters, PCB testing has become very simple. The Digital LCR meter is a compact, battery-powered and lightweight instrument.